India’s dirty secret is an oil market headache

The choking smogs that have made India’s cities the world’s most polluted in recent years have sparked a justifiable backlash against the use of petcoke.

The choking smogs that have made India’s cities the world’s most polluted in recent years have sparked a justifiable backlash against the use of petcoke. (Photo: Reuters)

What do you do when your dumping ground cleans up its act? That’s the problem confronting the oil market as the global shipping industry starts implementing regulations to limit its consumption of sulfur, a common impurity in crude that can cause respiratory problems and acid rain when it’s burned.

As we saw in a column Wednesday, rules on sulfur content coming into force at the start of 2020 will make the bunker fuel used in ships — traditionally the cheapest, dirtiest fraction from refining — cleaner than the median barrel of crude oil produced worldwide. As a result, the world’s refiners are going to have to find another way to get rid of their noisome by-products.

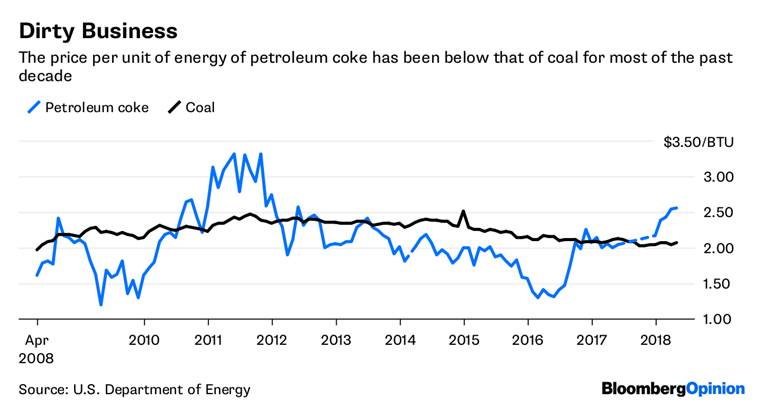

One popular way of doing this of late has been to sell it to India as a cheap coal substitute. Petroleum coke or petcoke is a spongy, solid residue from oil distillation that can be burned for fuel in the same manner as coal, and typically has a higher energy content.

Due to a loophole in India’s environmental taxes, petcoke has become an attractive raw material for power stations and cement plants. While plain old coal attracts a clean-energy levy that’s risen to 400 rupees ($5.83) a metric ton since it was introduced in 2010, petcoke has been exempt. With Indian prices for coal of comparable heating values in the region of 4,000 rupees a ton, that tax has been enough to tip the scales in petcoke’s favor. Similar levy issues have favored it over natural gas, too.

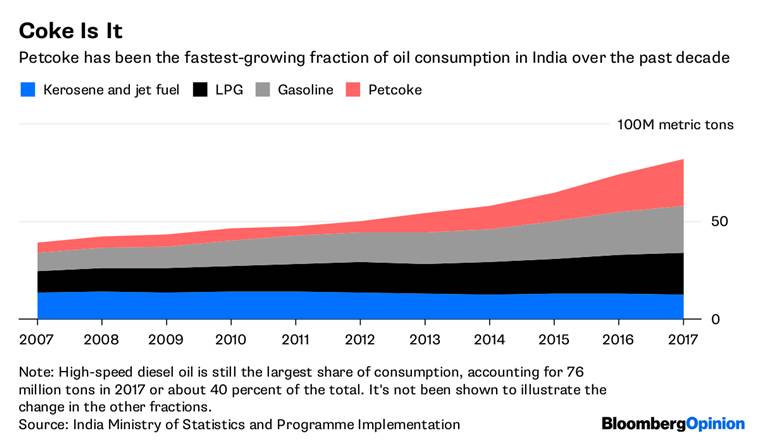

The results have been dramatic. Over the decade through 2017, petcoke was the fastest-growing fraction of oil demand in India, expanding at a 15 percent compounded annual rate. In the year through March 2017, the 24 million metric tons of petcoke consumed represented the second-biggest share of India’s petroleum consumption after diesel, outstripping even LPG and gasoline.

The problem with that is that while petcoke is richer in energy than coal, it can have 20 times as much sulfur, too. The choking smogs that have made India’s cities the world’s most polluted in recent years have sparked a justifiable backlash. The country’s Supreme Court last year banned the use of petcoke in New Delhi and adjacent states, before allowing a reprieve for the cement companies that consume about half of it.

Few expect that to be the end of the matter. New Delhi is planning a nationwide ban on using petcoke as fuel, Reuters reported in May, citing government sources it didn’t name. On top of that, officials have promised to look at measures to halt imports. That’s significant, because petcoke produced overseas now accounts for about 40 percent of supply, much of it from U.S. refineries processing heavy Canadian and Latin American crude.

Cement plants, which currently escape the court ban on the contestable grounds that all their sulfur is removed in the production process, might not continue to be exempt, either. Short of that, the government should at least change its clean-energy taxes so that the levy on petcoke is equal to that on coal.

While that will be great news for Indians’ health, it will be a headache for the global refining industry. The cheapest ways of getting rid of petroleum’s sulfur content have traditionally been to sneak it into lower-grade products, but tightening environmental regulations have progressively driven it out of diesel and now look certain to sharply reduce it from bunker fuel, too. It the petcoke safety valve is closed, it’s not clear what they’ll do with it.

It’s not a complete disaster. Refineries can remove the sulfur altogether and turn it into sulfuric acid, a prized raw material for the fertilizer industry and chemicals manufacturing that can even be fed back into refineries to produce ingredients for high-octane gasoline.

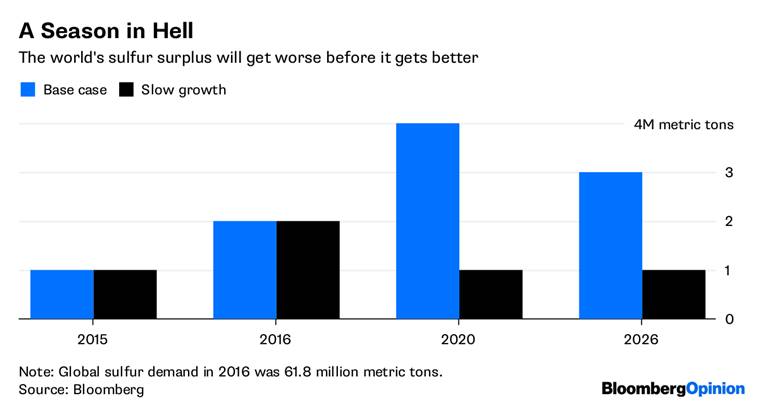

Still, the economics of that look distinctly shaky. Building sulfur plants is costly and takes up a lot of room, at a time when refineries aren’t looking to splurge on capex, according to Sushant Gupta, an analyst with consultancy Wood Mackenzie. Furthermore, the sulfur market is facing a surplus of about 3 million metric tons this year that could grow into a “sustained period of depression” after that, according to consultancy Integer Research, reducing the return from selling the element.

Refiners are used to offloading their bottom-of-the-barrel fractions at a loss to compensate for the more profitable volatile products like gasoline, diesel and naphtha, but the balance of that compromise is set to worsen in future. The cheap and cheerless path of pumping the oil industry’s impurities into the skies over India and Earth’s oceans is gradually disappearing. Cleaning up your act never looked so costly.

For all the latest Opinion News, download Indian Express App

No hay comentarios:

Publicar un comentario